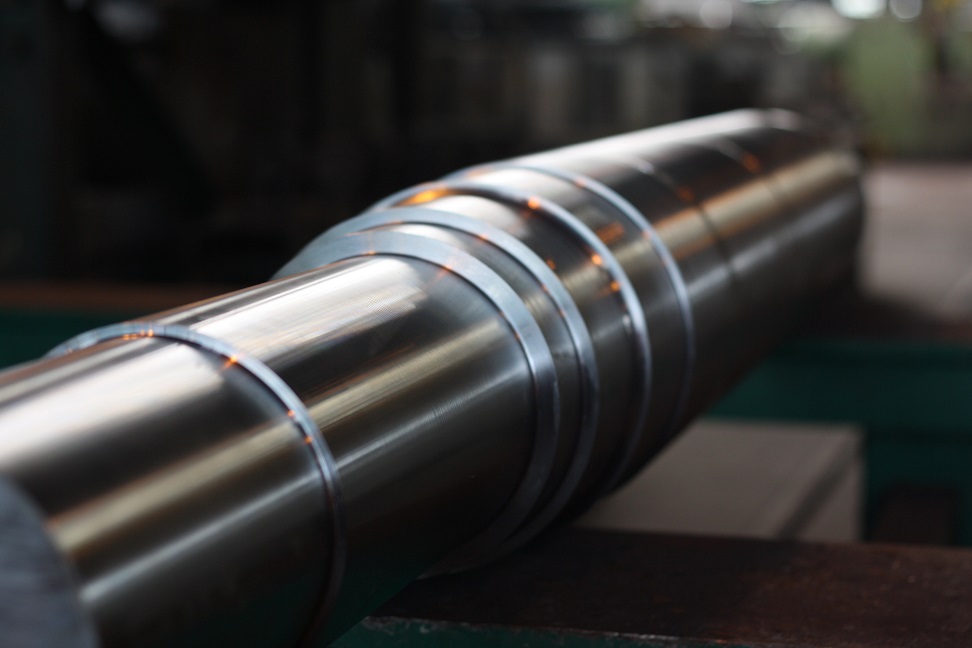

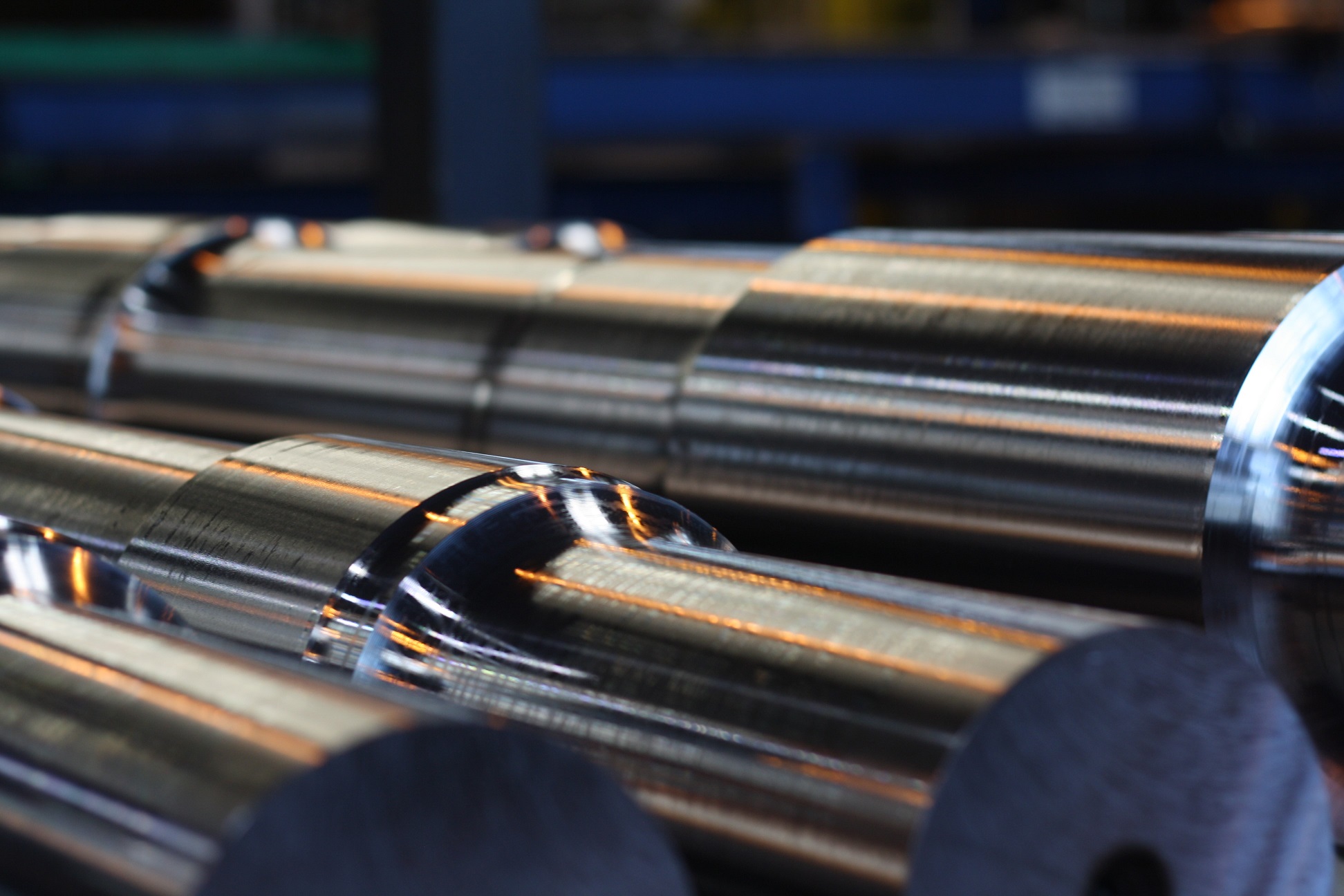

Proven quality

There are five good reasons for the exceptional life cycle of our wheelset shafts: the careful selection of materials, the superior design, the elaborate, close-contour forging and the high-quality tempering. And of course the mechanical pre-machining on process-optimised machines.

The material

The purpose of use and the customer’s requirements define the steel. We follow the latest standards. In any case, however, the quality meets the highest standards: rigorously tested, tried and tested thousands of times.

The manufacturing process

With our radial forging machine, we manufacture wheelset shafts close to contour and with reduced use of pre-material. Our blanks are individually adapted to the given contour and forged. Each shaft shape is unique and is adapted to the customer’s requirements.

Quality inspection

All common heat treatment processes are available to you as a customer: Tempering, normalising and the like. All wheelset shafts are ultrasonically inspected radially and axially and tested according to the applicable standards.

Deutsch

Deutsch